MadEdge Sharpeners

Discover our full lineup of professional sharpening tools designed for precision, durability, and comfort.

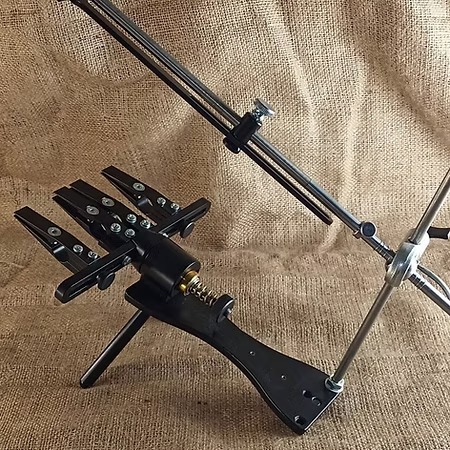

MadEdge Model 1

Modular sharpener with a rotary mechanism based on cutting-edge rotating clamp technology. Clamps are made of steel (not aluminum). All parts of the rotary mechanism are steel; rubbing surfaces hardened to 900HV. MadEdge system includes a spherical nut to compensate for screw skew on thin knives. Wear compensation is possible only in the MadEdge system. Antifriction bronze bushing in the hinge ensures smooth stone movement. Stone holder handle made of stained oak. Minimum grinding angle: 10° per side. Compatible with knives, scissors, and chisels. Sharpening angles from 10° to 40° per side. Stones fixed from 12 mm width and up to 220 mm length. Compatible with both blank and standard stones. Rotary mechanism accuracy: 0.2°.

- A spherical nut compensates for screw skew when working with thin knives.

- Steel parts of the rotary mechanism ensure durability.

- Compensation for wear of the turning mechanism is only available in the MadEdge system.

MadEdge with Digital Sharpening Angle Measurement

MadEdge with integrated Digital Sharpening Angle Measurement. This configuration avoids the installation of additional mass on the clamping frame and avoids additional pressure on the grinding stone. Combining modern technology with traditional engineering, this model includes a **built-in digital angle display** for precise sharpening every time. Perfect for professionals who demand accuracy.

- Digital LCD angle indicator (accuracy ±0.1°)

- Micro-USB rechargeable power system

- All model 1 features

MadEdge Model 2

Unlike Model1, it has an additional pair of clamps fixed in the center. All parts are made of steel, no aluminum. Friction surfaces are hardened to a hardness of 900HV. The clamps are equipped with a spherical nut to compensate for the misalignment of the screw when securing thin knives. Moreover, in the case of thread wear in the clamps, it is necessary to replace only the nut and screw, and not the entire expensive clamp. Parts are coated with a polymer wear-resistant coating that covers car wheels. There is a mechanism for adjusting the wear of the seats of the rotary mechanism. The guide is heat-treated to a hardness of 60HRC; for smoothness of movement, sliding is carried out along the bearing. The hinge has extended turning angles, which provides a comfortable sharpening of long knives. The stone holder has a substrate, which allows you to use stones with blank and without blank. The base is supported on 3 points, which ensures the stability of the sharpener on any surface.

- Reinforced ceramic sharpening wheel

- Adjustable sharpening resistance

- Silent operation mode

MadEdge for Convex Blades

1. Clamps are made of steel, not aluminum. 2. All parts of the rotary mechanism are also made of steel, and not of bronze and aluminum. Rubbing surfaces are hardened to hardness 740HV. 3. Only in the MadEdge system, the clamps have a spherical nut to compensate for the screw skew when attaching thin knives. 4. Only in the MadEdge system is it possible to compensate for the wear of the turning mechanism. 5. An antifriction bronze bushing is pressed into the hinge of the sliding assembly, which ensures an increased smoothness of the movement of the stone. 6. The handle of the stone holder is made of stained oak. 7. The minimum angle of grinding is 12 degrees per side.

Pro Tip: For best convex sharpening, rotate the blade gently while maintaining even pressure throughout the stroke.

- Dual-bevel correction system

- Supports edge angles 15°–45°

- Anti-glare surface with adjustable grip